Shaft Impact Crusher Is Suitable For Mineral Processing

Vertical Shaft Impact Crushers – G Model– MEKA

Vertical Shaft Impact Crusher (MVIG) Series is specifically designed for shaping the material after a cone crusher Rock on rock designation means a few and inexpensive wear parts compared to other alternatives Adjustable speed and adjustable cascade increases control on APPLICATIONS The strength of Secondary Impact Crusher (MSI) makes them ideal Secondary Impact CrusherVertical shaft impact crusher is an efficient fine crushing and shaping equipment, mainly used for crushing and shaping of medium and high hardness materials It is widely used in sand and VSI vertical shaft impact crusher working principle XingaonaiThe impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is Impact Crusher an overview ScienceDirect TopicsTo enable aggregate producers to react temporarily and effectively to these situations, SBM Mineral Processing has developed two semimobile impact crushers In the article, typical examples are presented to illustrate their Semimobile crushers for oversize comminution2022年8月29日 The Kinglink KLSeries Vertical Shaft Impact (VSI) crusher has had a huge impact on the global quarrying and minerals processing industries The Kinglink KLSeries VSI Vertical Shaft Impact Crusher machinerylinefo

Working Principle And Application Exploration Of Vertical Shaft Impact

2024年9月25日 Mining field: In the mining industry, vertical shaft impact crushers can be used to process ores of various hardnesses Its efficient crushing capacity and precise control of 2024年10月13日 Vertical shaft impact crushers offer a unique way to process materials with several advantages over traditional crushing methods Their ability to produce highquality The advantages and applications of vertical shaft impact 2025年4月3日 A vertical shaft compound crusher is a special type of crushing equipment that combines the characteristics of vertical crushers and impact crushers It usually consists of the rotor and impact plate of a vertical crusher, Vertical Shaft Compound Crusher JXSC Mineral2024年4月19日 Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore This is the reason why it is especially suitable for further processing or use Types of Crushers Explained: Everything You Canica Vertical Shaft Impact Crusher This crusher developed by Jaques (now Terex® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore Jaw crushers were found to produce RA with the most suitable grainsize distribution for concrete production (Molin et al, 2004 Impact Crusher an overview ScienceDirect Topics2015年6月23日 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An Impact Crusher Working Principle

Crushing 101 – Different types of crushers for distinctive needs

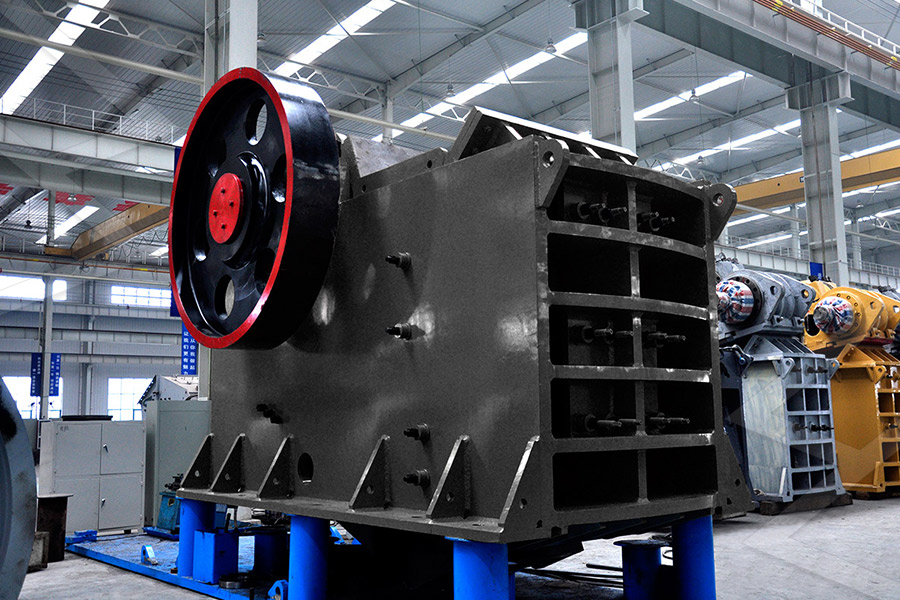

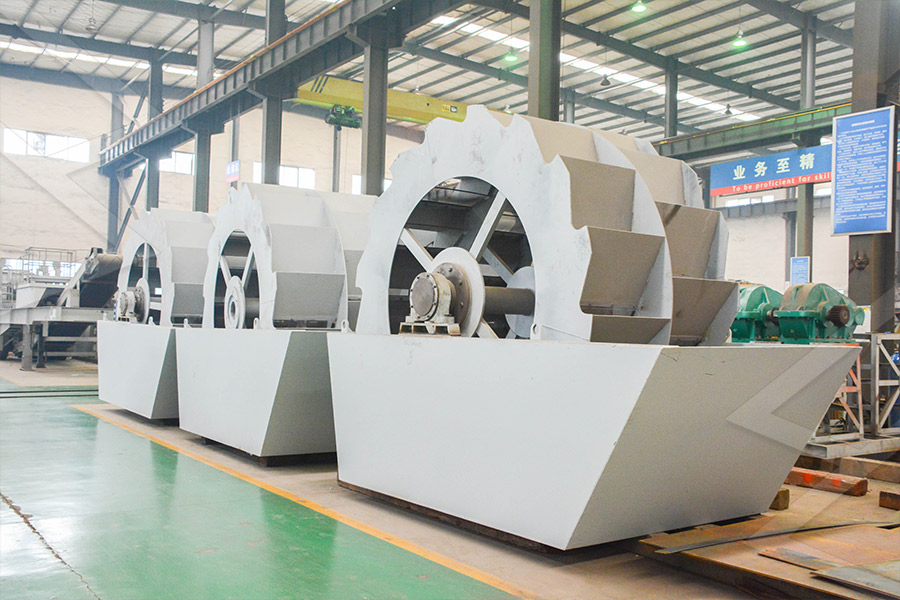

2020年12月17日 In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle 2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS2020年7月23日 Generally, it is not suitable to use hammer crusher, impact crusher, and other crushers need frequent replacement of subsequent wear parts What are the rock crushers suitable for crushing hard materials? The vertical shaft impact sand making machine can choose different crushing cavity types of “stone hitting stone” or “stone hitting The Top 5 Must Know Granite Crushers (With GIF) Mineral ProcessingPowerups VSI vertical shaft impact crusher is widely used in mineral processing, aggregate processing and construction recycling industries, besides, we have been committed to equipment optimization, such as simple and safe operation of the machine, long wear life of wearing parts, and we are aiming to satisfy all my customers worldwideVertical Shaft Impact Crusher2023年1月18日 The impact crushers are more suitable for smallscale stone production lines and handles some brittle materials If you have strict requirements on the grain shape of the finished product, you can choose an impact crusher, or add an impact crusher or sand making machine after the cone crusher Sand making and shaping stageHow to Choose Stone Crusher in Different Stages? DASWELL4 天之前 Vertical shaft compound crusher is also called vertical type crusher, compound sand making machineIt is a fine crushing equipment that combines the advantages of impact crushing and hammer crushing and is optimized with advanced technology It can achieve the purpose of fine crushing and sand making, and the finished product has better particle shapeVertical Shaft Compound Crusher JXSC Machinery

The Top 5 Must Know Granite Crushers (With

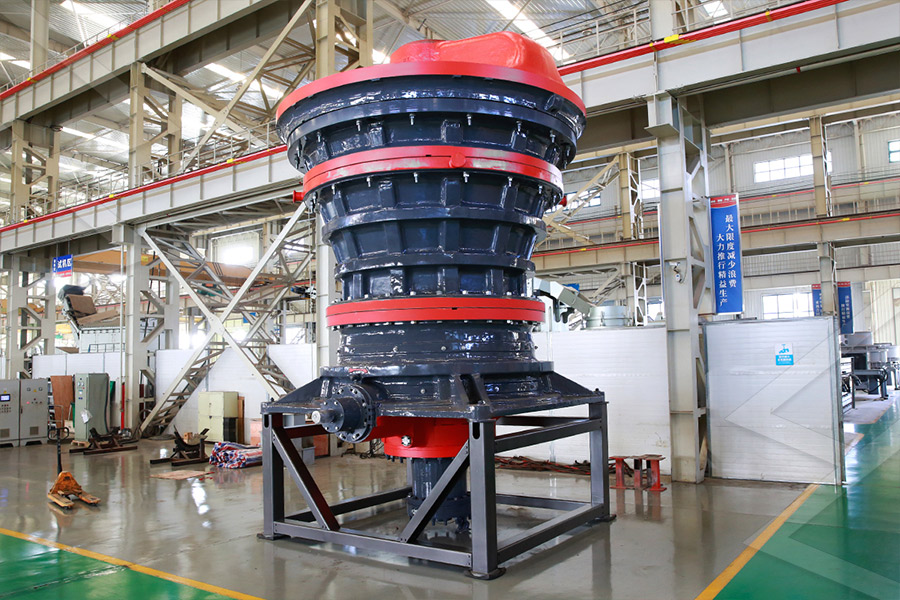

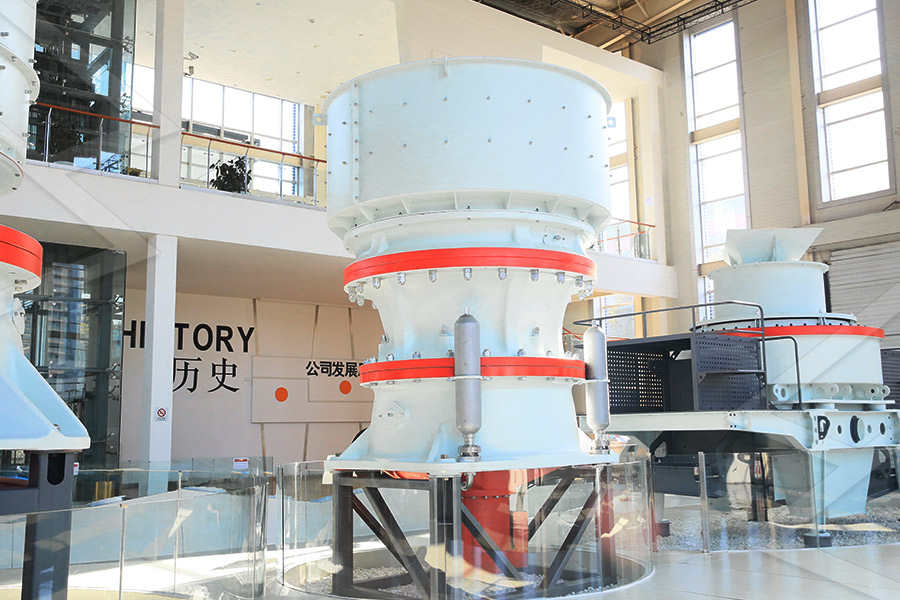

1 天前 Cone crusher is definitely the most commonly used product in the mediumfine crushing stage of hard rock crushing (sometimes it is also used for coarse crushing according to the situation) It has good wear resistance and 2025年4月3日 A vertical shaft compound crusher is a special type of crushing equipment that combines the characteristics of vertical crushers and impact crushers It usually consists of the rotor and impact plate of a vertical crusher, Vertical Shaft Compound Crusher JXSC Mineral2025年4月2日 Vertical Shaft Compound Crusher Structure Vertical shaft compound crusher, also called vertical shaft sandmaking machine, consists of a transmission device, bearing, upper machine cover, liner, hammer head, Vertical Shaft Compound Crusher JXSC Machine1Understanding Vertical Shaft Impact Crusher (VSI): a Principle of Operation: The VSI crusher operates on the principle of impact The feed material, typically minerals, is introduced into the crusher’s chamber where it is struck by a spinning impeller or rotorUnveiling the Versatility of Vertical Shaft Impact Crusher in 2025年4月2日 The impact crusher crushing the soft and very hard materials, even if there is moisture in the material The types of stone crushers are widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine materialsTypes of Stone Crushers Machine Mineral Processing2016年4月1日 It can be widely used in metal and nonmetallic minerals, building materials, artificial sand and a variety of metallurgical slag crushing and shaping; VSI6X1263 crusher suitable for the requirements of moisture content of materials below 20%; It can be used for coal and calcium carbide and other special combustible materials processingVSI6X1263 vertical shaft impact crusher

Review on advances in mineral processing technologies suitable

2022年4月1日 Mineral processing involves the liberation and concentration of economical metals and minerals from mineral resources for metal extraction (Lottermoser, 2010) The economic purpose of mineral processing is twofold: firstly, it reduces the bulk of the ore that needs to be transported and processed for metal extraction by using relatively cheap The BHS Rotor Impact Mill is a highperformance crusher with a vertical shaft The rotor impact mill enables customers to achieve a high reduction ratio and excellent particle shape The mill (Fig 6) is suitable for crushing all low to moderately abrasive mineral BHSSonthofen offers also Rotor Centrifugal Crusher (Fig 7)Mobile Mineral Processing Equipment: The State of the Art 2020年8月18日 While the process of testing and evaluating the rock adds time and another layer of complexity, it is vital to the success of the circuit Whether you need a compression or impact crusher, each type of crusher has its own benefits and excels in different applications This statement is valid for all flowsheet designUnderstanding comminution: Compression versus impact The whole process of breaking things down first happens thanks to an eccentric shaft, which makes the moving jaw swing and apply the crushing force One really handy thing about jaw crushers is that you can change the size of the end product by Mineral Processing Solutions: Exploring Types of Jaw CrusherMVIG Series vertical shaft impact crusher are designed to be used in tertiary or quarternary stage crushing These crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well Vertical Shaft Impact Crushers – G Model– MEKA2018年12月26日 processing or to size suitable for the intended end use The goal of a crusher is to crush the Material crushed in an impact crusher is an example of dynamic impact When the material is crushed in an impact crusher, the freely falling working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing Construction, Working and Maintenance of Practical

.jpg)

Crushing Mineral Processing 911Metallurgist

2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the 2025年3月28日 1 Impact Crushers Impact crushers use impact force to crush materials, and you can use soft and mediumhard rocks with this machine These crushers can complete primary and secondary crushing, making them suitable for applications in recycling and quarry industries Impactors come in two different types:Choosing the Right Crusher: Types, Features Applications2019年1月10日 2 Impact crushers can process materials up to 500mm in size and 350MPa in strength to produce cubeshaped output They are used in industries like construction 3 Vertical shaft impact crushers use highspeed rotors and have features like low energy use, stable operation, and suitability for sand productionCrusher and Its Types PDF SlideShare2025年4月3日 The roll crusher is suitable for fine crushing the medium hardness rock with compressive strength ≤160MPa Impact Crusher Hammer Crusher Cone Crusher Jaw Crusher Mineral Processing Consulting Services Other Capacity(T/H) 010 T/H 1050 T/H 50100 T/H 100300 T/H 300500 T/HRoller Crusher JXSC MineralVertical Shaft Impact Crusher: Revolutionizing Material Reduction Our stateoftheart Vertical Shaft Impact (VSI) Crusher is engineered to deliver exceptional performance in crushing a wide range of materials, from soft rocks to highly abrasive minerals Our VSI crusher is suitable for a variety of applications, including mining Vertical impact crusher Rock machinery3 天之前 Rock Ore Crushing Circuit Mineral Processing with Flowchart, Find Details and Price about Rock Crushing Stone Crushering from Rock Ore Crushing Circuit Mineral Processing with Flowchart Yantai Huize Mining Engineering Co, Ltd cone crusher, hammer crusher, roller crusher, vertical shaft impact crusher, etc In the crushing process, other Rock Ore Crushing Circuit Mineral Processing with Flowchart

Understanding Comminution: Compression versus impact

2020年9月16日 Weir Minerals offer two types of impact crusher suitable for primary and secondary crushing: horizontalshaft impact (HSI) crushers and verticalshaft impact (VSI) crushers Cone crushers are typically used in the secondary or tertiary stage after a jaw crusher has begun the reduction process earlier in the circuit They process smaller 2019年3月6日 The Vertical Shaft Impactors or VSI Crusher are one type of impact crushers, which offer higher reduction ratios at a lower energy consumption These impactors can be considered as a ‘stone pump’ operating like a centrifugal pump The material is fed through the centre of the rotor, where it is accelerated to high speed before being discharged through VSI Crusher Vertical Shaft Impactor 911Metallurgist2024年4月19日 Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore This is the reason why it is especially suitable for further processing or use Types of Crushers Explained: Everything You Canica Vertical Shaft Impact Crusher This crusher developed by Jaques (now Terex® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore Jaw crushers were found to produce RA with the most suitable grainsize distribution for concrete production (Molin et al, 2004 Impact Crusher an overview ScienceDirect Topics2015年6月23日 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An Impact Crusher Working Principle2020年12月17日 In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle Crushing 101 – Different types of crushers for distinctive needs

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the 2020年7月23日 Generally, it is not suitable to use hammer crusher, impact crusher, and other crushers need frequent replacement of subsequent wear parts What are the rock crushers suitable for crushing hard materials? The vertical shaft impact sand making machine can choose different crushing cavity types of “stone hitting stone” or “stone hitting The Top 5 Must Know Granite Crushers (With GIF) Mineral ProcessingPowerups VSI vertical shaft impact crusher is widely used in mineral processing, aggregate processing and construction recycling industries, besides, we have been committed to equipment optimization, such as simple and safe operation of the machine, long wear life of wearing parts, and we are aiming to satisfy all my customers worldwideVertical Shaft Impact Crusher2023年1月18日 The impact crushers are more suitable for smallscale stone production lines and handles some brittle materials If you have strict requirements on the grain shape of the finished product, you can choose an impact crusher, or add an impact crusher or sand making machine after the cone crusher Sand making and shaping stageHow to Choose Stone Crusher in Different Stages? DASWELL4 天之前 Vertical shaft compound crusher is also called vertical type crusher, compound sand making machineIt is a fine crushing equipment that combines the advantages of impact crushing and hammer crushing and is optimized with advanced technology It can achieve the purpose of fine crushing and sand making, and the finished product has better particle shapeVertical Shaft Compound Crusher JXSC Machinery